Thank you for stopping by and checking out this pet project of mine. A slight bit of background, I purchased my Anycubic Kobra back in November of 2022 and started this hobby. As most hobbies tend tend to do, it started small and eventually grew into what feels like a part time job! Sticking with just prints at first, my need to tinker and the lust for a deeper understanding resulted in the pursuit of modifying this printer… heavily. You can probably already see where this is going?

It wasn’t long before I pursued installing Klipper, and then modifying the Z Axis for better control of my prints. Then came replacing the mainboard with a more featured and powerful board. Doing these things opened up the ability to modify the printer more easily with a wider range of modifications. But, I’m the type that likes to set an unnecessary challenge for myself. Which gets us to the topic of this specific modification. Can I install a different extruder in a fashion that works with an unmodified Kobra?

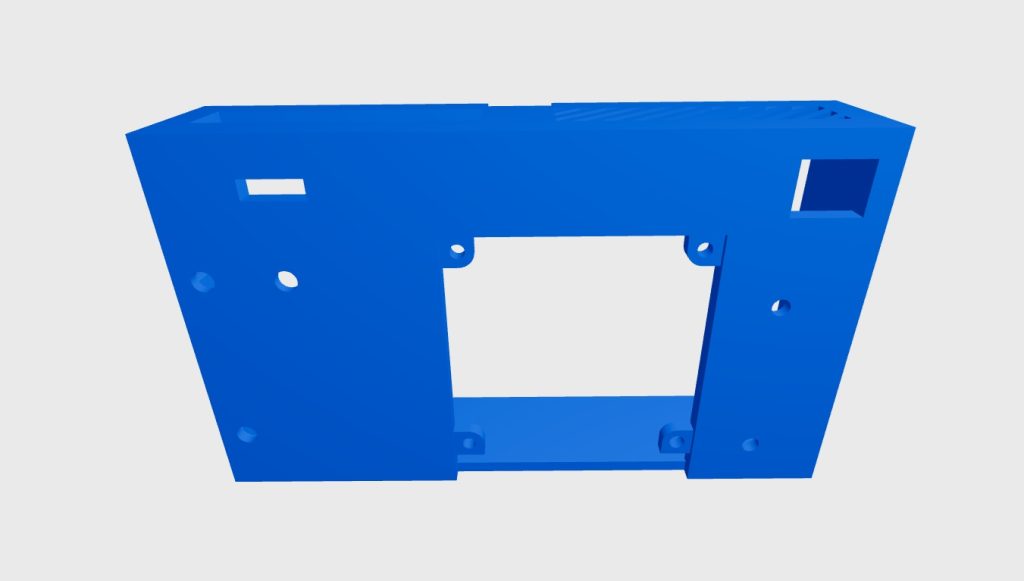

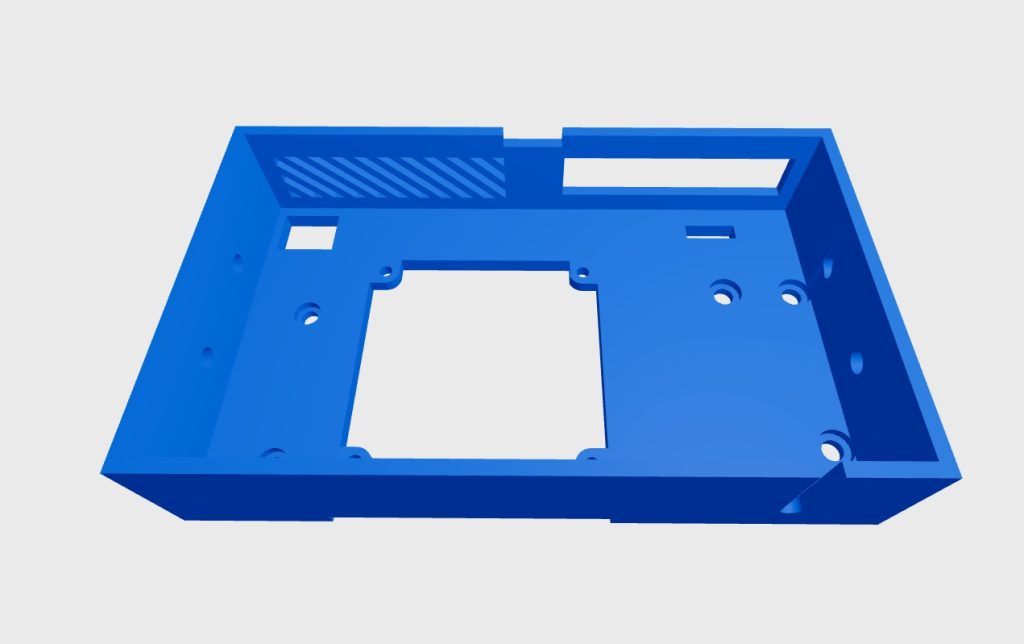

First, need a baseline for a reference point. I set about recreating the stock tool head mount. Not the worse undertaking since I have calipers and 3d editing software (Blender isn’t the most ideal, but let’s not try to learn a new program at this point). Once that part was accomplished, I found what the new extruder was going to offset the nozzle versus the stock extruder. Simple enough, this should be a nearly completed endeavor? Wrong.

I had the first version quickly enough, printed it out of PLA for a quick mock up. Test fit it, realized I mixed up some variables, then went back to editing the toolhead. Soon enough I had version 2 printing, and was excited to see if I was getting anywhere. Installing it was mostly successful, the extruder lined up, and it would be a functional print. The new model was somewhat of a skeleton, with the cutout for the part cooling fan, which kind of gave it a certain flair. But, the ABL sensor was not in the right position. Not the end of the world, I am using Klipper and could quickly modify the offset to be correct, to insure the ABL was accurate.

This wasn’t the goal, though. I had set out to make it possible for someone to use the stock firmware (Marlin), and be able to use the stock components. Back to Blender, another cup of coffee, followed by staring at my 3D model until I started to lose what sanity remained. I finally figured out a solution, it was a compromise, but a small one. The ABL requires a spacer to install in a stock offset to the nozzle. This does mean that a few screws will need to be changed out. This will allow full use of the stock Marlin firmware, but will require the correct screws and the new extruder w/ heatbreak for the Bill of Materials (BoM).

You can still use the stock Stepper mounting bracket, ABL, fan w/ cooling duct, and even the toolhead circuit board!

Continue to BoM